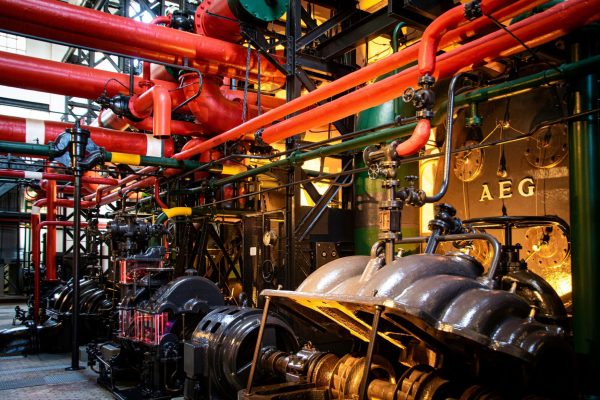

In the harsh environments where industrial equipment operates, protection isn’t just a luxury—it’s a necessity. Industrial equipment powder coating provides a solution that delivers exceptional durability, resistance, and aesthetic appeal. As machinery faces demanding conditions, from extreme temperatures to corrosive substances, a proper protective finish can mean the difference between equipment that thrives for decades and assets that require constant maintenance and premature replacement.

What Makes Industrial Powder Coating Superior to Traditional Paint

Industrial powder coating outperforms conventional liquid paint in virtually every measurable category. Unlike wet paint that requires solvents, powder coating uses dry powder applied electrostatically and then cured under heat. This process creates a finish that’s significantly tougher than traditional methods.

The powder coating process bonds the finish to the equipment at a molecular level, resulting in:

- Superior adhesion that prevents chipping, peeling, and flaking

- Enhanced corrosion resistance, even in harsh chemical environments

- Exceptional impact resistance that withstands daily operational abuse

- Greater abrasion resistance that maintains appearance despite friction and wear

- Environmental benefits from the solvent-free application process

For heavy machinery, manufacturing equipment, and tools that face demanding conditions, industrial equipment powder coating provides unmatched protection that simply lasts longer.

The Science Behind Industrial Equipment Powder Coating

Understanding how powder coating works helps explain its effectiveness. The process begins with thorough surface preparation—perhaps the most critical step. After cleaning, masking, and pretreatment, the powder is applied using an electrostatic spray process where charged particles adhere to the grounded metal surface.

When the coated piece enters the curing oven, the powder melts and flows into a continuous, uniform finish. Chemical reactions during this thermal bonding process create complex polymer structures with exceptional protective properties.

This science explains why industrial powder coating creates finishes that remain intact and attractive even after years of exposure to elements that would quickly degrade traditional paint applications.

Common Applications for San Diego Industrial Powder Coating

San Diego’s diverse industrial sector relies heavily on powder coating technology. From maritime equipment facing saltwater exposure to manufacturing machinery handling abrasive materials, proper coating extends operational lifespan significantly.

The region’s industrial businesses frequently apply powder coating to:

- Heavy machinery components

- Manufacturing equipment

- Agricultural implements

- Food processing equipment

- Automotive parts and assemblies

- Metal fabrications

- Industrial shelving and storage systems

- HVAC equipment

At Anocote Powder, we’ve serviced San Diego’s industrial equipment powder coating needs for everything from massive agricultural machinery to precision manufacturing equipment. Our specialized processes ensure your equipment maintains peak performance even in challenging environments.

Cost Benefits of Professional Industrial Powder Coating

While initial investment in quality coating might exceed basic industrial equipment painting, long-term economics strongly favor powder coating. Financial advantages emerge through extended service life, reduced maintenance requirements, and improved operational efficiency.

Equipment protected with industrial powder coating typically requires fewer repairs and stays in service longer. This translates directly to reduced downtime and replacement costs. Additionally, powder-coated surfaces clean more easily, reducing maintenance labor and allowing equipment to operate at optimal levels.

When factoring total cost of ownership, powder coating typically delivers return on investment within the first few years through these operational savings.

Environmental Advantages of Modern Powder Coating

Today’s industrial powder coating processes offer significant environmental benefits compared to traditional finishing methods. Unlike solvent-based paints that release volatile organic compounds (VOCs) into the atmosphere, powder coating is virtually emission-free.

The process uses no solvents, produces minimal waste, and excess powder can be recovered and reused. This dramatically reduces environmental impact while helping businesses meet increasingly stringent regulatory requirements.

For San Diego companies focused on sustainable operations, switching from industrial equipment painting to powder coating represents a significant step toward greener manufacturing processes.

How to Choose the Right Industrial Powder Coating Service

Selecting a qualified powder coating provider requires evaluation of several factors beyond just price. Quality control processes, equipment capabilities, material knowledge, and proven experience with similar applications should all influence your decision.

When evaluating potential providers, consider:

- Years of experience specifically with industrial applications

- Range of powder options and formulations available

- Size capacity and ability to handle your equipment dimensions

- Surface preparation capabilities and standards

- Quality control measures and testing procedures

- Turnaround times and scheduling flexibility

- Customer references from your industry

The right provider will ask detailed questions about your equipment’s operating environment to recommend the optimal coating system for your specific needs.

Preparing Equipment for Industrial Powder Coating

Proper preparation before coating significantly impacts final quality and longevity. For optimal results, equipment should be thoroughly cleaned of all oils, greases, and contaminants. Existing finishes typically need removal, and surfaces often require abrasive blasting to create the ideal profile for powder adhesion.

Some materials, particularly certain alloys, may need chemical pretreatment to ensure proper bonding. Masking must be precisely applied to protect threaded areas, bearings, and other components that shouldn’t receive coating.

Working with experienced professionals ensures these critical preparation steps receive the attention they deserve, resulting in coatings that perform to specification.

Why San Diego Businesses Trust Anocote Powder for Industrial Equipment Protection

When durability matters, San Diego industrial powder coating customers choose Anocote Powder for their most demanding applications. Our specialized processes, state-of-the-art equipment, and experienced technicians deliver consistent, high-quality results for even the most challenging industrial equipment.

With decades of combined experience, our team understands the unique challenges faced by different industries and tailors coating solutions to your specific operational environment. From corrosion protection for marine equipment to chemical resistance for processing machinery, we engineer solutions that extend equipment life and reduce maintenance requirements.

Contact Anocote Powder today to discuss how our industrial powder coating services can protect your valuable equipment and improve your operational efficiency. Our team will provide a comprehensive assessment and recommend the ideal coating system for your unique needs.